^ I'll be ordering this within the next few weeks!!

Sent from my iPhone using Tapatalk

I have not posted much for updates to the car for a while so time for a status update

The first day I fired up the car it turned over no problem and it was running well. After a few more times firing up the car and shutting it off I started having issues with the starter relay, then it failed so I just had to jump the starter to fire the motor up. At times the engine seemed difficult to crank over, I wrote this off as being due to battery relocation and cables not large enough and hooked up a jumper pack. Then a couple days later I have another issue that came up with a couple small ground wires that melted when I was trying to crank the motor over. So I needed to step up to some larger ground cables and installed a few more 4 gauge grounds and I no longer had an issue with wires melting, but the engine was still difficult to crank at times...Note to self, dont ignore a hard cranking issue

The car ultimately died on me one day on my way home for lunch and the motor was locked up. I tried turning the crank with a breaker bar and socket, but no go. It was time to pull the motor after driving it for a few short days and only about 20 miles of driving. A few people will wonder about the tune that the car had as well, but I can assure you there were no alarming knock counts leading up to this. I found two spots with 6 counts as the highest I logged and that was during first day of start up, I was extremely conservative with the tuning to start with so I didn't have to worry about high knock counts being an issue while driving to data log. I did not have an oil pressure gauge installed at the time (something being added now however), but given the condition of the motor when I tore it down it is fair to say the motor was not well maintained at all...my own fault for not doing a more thorough teardown/inspection.

Well, onto tear down photos

Pulled the plugs, all looked fine nothing smashed so i was happy besides the obvious running rich

Slowly disassembling the motor and checking things out. Once I got this on the engine stand I was able to break the crank free to rotate it around and you could feel where it was binding up and having that cranking issue...it was all making sense now.

Look at the oil sludge build up on this bottom end...5-6mm thick at least and was a bitch to clean up;

Here was the culprit issue;

Main bearings not so great from all the contaminated material;

Slowly cleaning things up and inspecting clearances and everything;

Checked the ring gaps on the piston rings that came out of the motor and these were the readings if anybody was interested;

Pistons didn't look bad, but they were all cleaned up a bit more and will be swapped to a new set of the stock 75 rods. I chose to use the stock rods vs 74s because I am only doing a basic short block refresh for this engine...a built motor will come later, right now I just want to drive this thing and enjoy it;

The oil pump needed to be gone through to inspect the damage. I really didn't want to buy a new oil pump so I just cleaned this up and checked the clearances, besides the obvious visual signs of wear this thing still checked out well within specifications. Since I will also be installing an oil pressure gauge this time around I am not real worried about re-using this pump either.

Now since the crankshaft needed to be machined and repaired I contacted Mile High Crankshafts out here in Denver to inquire about the repair and additional machining. With the one journal to be repaired and having the crankshaft nitride coated again to bring it back to OEM specs it would have been a $500+ repair bill. Fortunately I was offered a deal on a good used crankshaft so I picked that up and will just save the other crank for another engine built later

I cleaned up the engine block a little more, honed the the cylinders, and repainted the block with a wrinkle black paint which I am happy with how it came out.

I am slowly working on the reassembly, just waiting for bearings and piston rings to come in so I can get going on putting things back together again. As much as it sucked to have the engine crap out, I am glad that it happened now and now during a trip.

- - - Updated - - -

Another batch of the Distributor Adapter plates done, already sold 3 from this batch which puts us up to 8 MIVEC swaps out there as of now.

Last edited by SPD_FRK; 02-26-2016 at 01:31 PM

^ I'll be ordering this within the next few weeks!!

Sent from my iPhone using Tapatalk

Great Job This is Passion I tell ya Great to see people dedicated with there projects keep up the good work mate! Props!

Awesome, I can't wait to receive it. You can contact me on Instagram. It will be easier to reach me.

Please send me the email asap on information statues update. [email protected] thank you

Sent from my iPhone using Tapatalk

Last edited by 8gtorque; 03-08-2016 at 10:38 PM

People ask once in a while about the difference between the Non-MIVEC and MIVEC pistons so figured I would share a couple pictures of those side by side for people to visualize.

Making some progress with the short block, taking my time mainly. All parts/gaskets are here and getting it together at least at this point. Here I am polishing the bearings to final fit for oil clearances

Setting up the Plasti-Gauge

Final assembly for the crankshaft, heavy on the assembly lube

Next up working on putting together the rods and pistons, and checking ring gaps.

- - - Updated - - -

Finishing up the short block assembly this weekend. Here I am getting all of the connecting rod clearances sorted out for the bearing sizes to be used on each one.

Getting the top end put together now

Thinking about some different plug wires now since this set needs to be replaced

- - - Updated - - -

A little tease of the new wheels I picked up a few weeks ago for a great deal. Getting them refinished and hopefully on the car in the next couple weeks.

Way to bounce back. At least you have peace of mind knowing the ins and outs of the motor now. Looking fwd to the new wheels.

Nice update, that last engine shot should be framed and turned into a motivational picture. Are those oem 74 wires? IIRC the Accel wires I used to run on my 72 fit the 75 as well, and they are nice quality.

I need to upgrade the wires mainly, this was just the old set from the 72. Hopefully I will have the new set installed in a coupe weeks since I have the engine just about ready to go, should be able to fire up this week I think.

I picked up the newest addition to the intake system this weekend and will begin testing and flow documentation in the coming weeks. More information can be read here

http://www.blackheartmotors.net/blog...hm-maf-adapter

Last edited by SPD_FRK; 04-11-2016 at 11:41 AM

I am working on getting the OEM exhaust fitted with the motor on the stand since it just makes things a little easier. The MAF adapter is also installed just for the photo...massive inlet ^_^

Spent the weekend working on the car and getting a few things cleaned up some more. The last time I installed the engine and transmission I didn't bother cleaning the transmission up.

It bugged me how nasty it looked so I spent a good bit of the day Saturday cleaning the case up a with a wire wheel. Nothing perfect but its a nice improvement from what it was, and looks a lot better.

I debated about modifying the wiring harness and getting everything tucked away neatly, but decided it was much work for now. To make it easy I am going to pick up another complete harness to redo so I can swap them out.

Everything is ready to fire up again, just need a new water pipe O-ring ( :rant: ), then I can get the water crossover pipe back on and fill the cooling system. Should have a start up video later this week.

That maf adapter is so nice compared to mine. I won't mention names, but for $10 I guess I cant complain too much. The bolt holes didn't line up the greatest, casting marks on the inside, and the sides are slightly sharp and less blended.

I don't mean to make it seem the maf adapter overshadows the progress being made. I just find it impressive when parts designed to have the most efficiency no matter how simple they are.

The MAF adapters that most people are using work well for that quick installation of any aftermarket intake system (or just a filter even), plus like you said they are very cheap to buy. There is nothing wrong with them, but by design they simply cannot offer what the BHM MAF Adapter will for the airflow capability.

The car now runs and moves under its own power as of last night. I have some things to finish up still with exhaust and wiring before its back to 100% but I am getting there.

Way to go on getting everything finished. Do you need a filter for your adapter? I have a 4.5" dc sports dry filter I think you might like. Its has a metal top and bases coated in wrinkle black that would go good with your manifold. Also has a funnel top and velocity stack base. I got mine on ebay, price wasn't bad either.

Sounds mean on my injen so I can only imagine on your car. Also can't really tell but are you using any piping for intake? If so seems short and direct.

Nice, can't wait to see how you finish it.

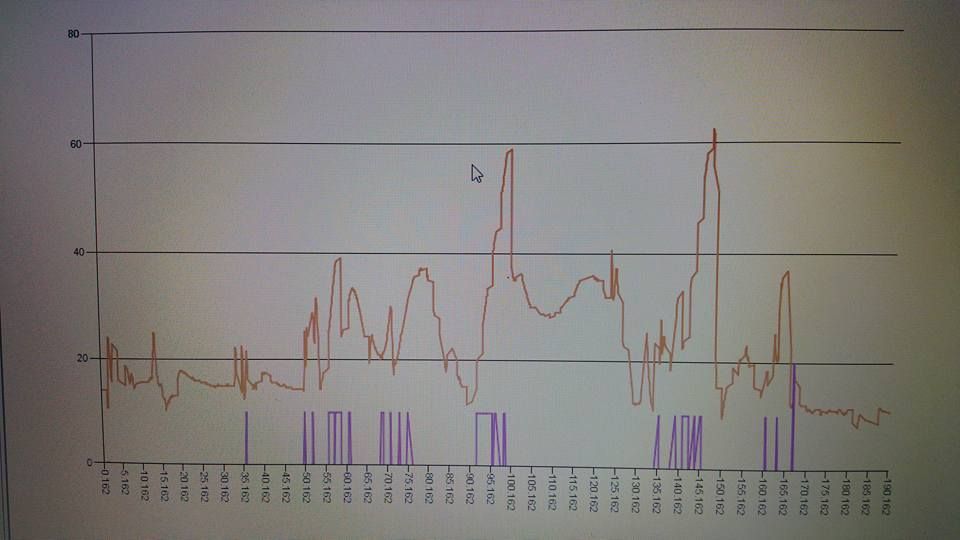

Here are some more screenshots of a couple logs from going around the block. These are with MIVEC activated via a momentary button simply for investigating the knock.

As you can see from the logs there is minimal knock so far, with/without MIVEC operation. I can't say exactly where MIVEC is being triggers as this was just a temporary setup with the button to see how things are responding. Fueling still needs adjustment at this point, but the data speaks for itself in regards to the knock.

3/4 Throttle up to just under 6000RPM-

3/4 Throttle roughly 4500RPM and above 110% load-

This is an overview of the entire log from start to finish (from leaving the parking lot around the block and back). Minimal knock counts through the log-

Looking good so far.

When swapping the motor out can the distributor and spark plug wires be transferred over to the 75?

After your adaptor I mean.

Sent from my iPhone using Tapatalk

Last edited by 8gtorque; 05-19-2016 at 12:34 PM

Nothing new really to update, just been driving the car quite a bit lately. So far I have racked up about 2000 miles on the fresh rebuild and pulling about 26-27mpg which wasn't too bad. It is definitely doing really well in the mountains for the increased power.

This past weekend I took the car up Mt. Evans here in Colorado (Highest paved road in North America at 14,200ft), that was an interesting drive.

Who needs guardrails ?

Bookmarks